|

|

WWW.RLYACHTS.NET

|

RL24, RL28, and RL34 Trailable Yachts

from Rob Legg Yachts

|

RL Yacht Owner's Discussion Forum

|

Return to the Forum List Leaking keel bolt Leaking keel bolt | My keel bolt keeps leaking - slowly.

I loosened off the nut then tried to back the bolt out by turning the head of the bolt. The head of the bolt then came off. But I could turn it back on.

I suspect the bolt is rusted into the centreboard. As the centreboard is lowered it breaks the seal of the bolthead and nut on the centre case.

Is there a way to take such a bolt out so I can get the centreboard out for a sand blasting and then get a board which will pivot without turning the pin.

| |

|  Re: Leaking keel bolt Re: Leaking keel bolt | Robert.

The original bolt would have been 316 stainless, and I find it incredible that the head would have screwed off, however I had heard of bolts being removed and replaced with steel bolts of a larger size just to fill the original clearance between the keel and the bolt diameter.

This was wrong because the difference had the purpose of allowing good clearance to prevent binding.

If the bolt is in fact steel and the head does screw partly in to the keel then the only solution I can think of is to try tightening the nut side and see if it will pull out with the assistance of some tapping from the opposite end, otherwise you may have to try drilling it out.

Note. You will have to support the keel at the front end first.

| |

| |  Re: Leaking keel bolt Re: Leaking keel bolt |  Robert, sounds like your biggest issue is to get the bolt out, using Rob Legg's method above should do it. Once you have it out it might be the time to come up with a different idea for a pivot bolt. this is what I have done. Robert, sounds like your biggest issue is to get the bolt out, using Rob Legg's method above should do it. Once you have it out it might be the time to come up with a different idea for a pivot bolt. this is what I have done.

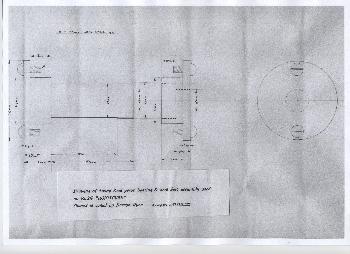

PLANS FOR RL24 SWING KEEL PIVIT PIN

On most yachts with a swing keel the sealing of the pivot pin on the centre case is a challenge many yacht owners have had to endure. There may be many other systems which have proved successful, but the following is one I have made.

The attached plan is one which has proved successful over a large number of competitive racing seasons.

The pivot unit is made out of Stainless Steel & is easy turned up in a machine shop. The only dimension which may need to be adjusted is for the fibreglass thickness of the centercase. This can be determined when the keel is removed, & a more exact measurement can be taken from the port outer side of case to the starboard outer side of the centre case, thus giving the exact width required.

It is assumed that all the castings of the keels for RL24 are the same dimensions therefore the 40 mm wide Bering surface should be adequate, BUT one thing than must be done is to drill the hole in the keel to 22mm diam & with the bearing surface on the pivot pin turned down to 21mm this will allow for any rust build up while the yacht is not being used.

Another suggestion (which I have not done) is to insert a sleeve of stainless steel thus eliminating the rust build-up problem

Experience has found that it is essential to have this 1mm clearance

The “Keel Bolt” is stainless steel – 15 mm diam. & 100 mm long, this needs to be a reasonable neat fit & a washer should be used both ends when installing the pivot pin.

It will be noted that there are 4 X 4mm stainless steel metal threads, two in each side of flange. These need to be 10mm long and thread taped through the flange and also taped into the fibreglass on the plate case.

The above mentioned metal threads are required to prevent the pivot pin assemble from rotating when the keel is being raised or lowered.

A good silicone grease is all that is required to make the unit water tight between the metal to metal faces, I use Sikaflex between the outside edge of the keel case and the underside of the flange.

| |

| | | |  Re: Leaking keel bolt Re: Leaking keel bolt | Thanks very much for your diagrams and instruction Darryn.

I will just try one more time but this time with greased rubber washers.

If it comes to it - drilling the bolt out of the keel - the stainless would be softer than the steel and then the advancing drill bit would be kept centred by the steel keel - is that correct?

| |

|

Return to the Forum List Add a message to this discussion |

|