There is an old adage that I am a firm believer in: “The only man who never made a mistake never made anything”. During my early years I certainly made my share of mistakes!

When stainless steel first made its appearance all we could get was off-cuts of dubious quality from a local sink manufacturer, and it was a far cry from the brass and mild steel that we had been using to make our homemade boat fittings. This new material was almost unworkable; a hacksaw wouldn’t look at it, and drill bits hated it.

And so it was that one Saturday morning before that afternoon’s race, we decided to increase the purchase power of the tackle that tightened our forestay. The previous week we had blamed a sagging jib luff for our poor showing and decided to add the extra block. First we needed a short pair of sister plates and, with difficulty, cut two pieces off a strip of stainless steel. All we needed then was to drill the necessary holes to attach the block.

Here we were with one of those now old-fashioned big “Egg Beater” hand drills, and having a lot of difficulty getting the drill to even make a dent in the stainless steel, let alone make a hole. My mate made the suggestion that we use a smaller drill to make a pilot hole first, and I should sit on the drill while turning it. He held the strip to the rigging deck with his fingers. OK give it a go!

I sat on the drill and turned as hard as I could. The drill bit broke at its tip and the remaining piece with all of my weight on it went sideways, and right through his thumb and pinned it to the decking. I was left in no doubt that I had caused him a lot of pain, and having to turn the drill in the opposite direction to remove the drill from his thumb only added to his agony.

Dipping the thumb in a bottle of iodine and adding a bandage proved a reasonable way to fix him up and we proceeded to get on with rigging the boat and sailed that day without the new fitting.

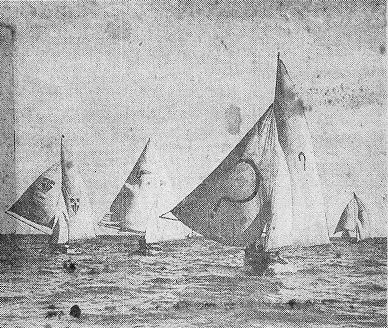

This is the only photo of "Mystery" (with the ? on the sails), a fourteen footer at StKilda during

the late forties. The club at that time had around thirty boats that sailed regularly, I sailed it

for a year before building a moulded hull over the top of it, and that became the first ever

moulded ply hull as far as I know in Australia.

Of course the shape was not ideal. The old cedar planked hull would have weighed around 200 Kg,

and was designed to carry a crew of four or five, and my hull only weighed around 60 KG

and with the smaller rig had only a crew of three, but never the less was a lot faster and was

the start of the light displacement boats.

The following Saturday, and even though I had made the said fitting during the week, I still found myself rather unpopular. However with the new block in place and with twice the tension on the jib luff, we reckoned that it twanged at about “G” sharp and should improve our performance a lot.

With the boat rigged and chocked up out on the beach we sat down on the sand beside it to eat our lunch. I decided to give our new tackle just one more tighten up first, and reckoned that the shrouds were now a pitch higher still.

Here I must explain that our mast, being oregon 8 meters long, was a thin walled hollow section of about 130 x 80 mm, and very rigid as was the fashion then. It had no other external rigging other than shrouds set around 350mm aft of the mast, and the forestay set off a bow sprit. To set up the forestay tension we had used a 3 to1 rope tackle, and the new block off the end of that, which made a 6 to 1 purchase, so with a 20Kg tension on the rope we had 120 Kg tension on the forestay. But what we didn’t take in to account was the shrouds being only 350 mm aft of the mast, had a tension of 700 Kg so no wonder you could play a tune on them, and now the mast had a compression load of 820 kg.

I was just munching in to my last sandwich and looking forward in anticipation to today’s race when there was a mighty BANG, and the mast exploded into splinters, one big piece burying itself deep in the sand close to where we were sitting.

We were used to this sort of disaster and it meant another week of late nights or early mornings, and we wouldn’t consider missing another Saturday’s sailing.

A mast that bent a little would have relieved itself of that excess compression load.

The main problem in those times was that mainsheets were taken off the centre of the keel (no tracks available then) so in a fresh breeze and puffy weather the sheet had to be eased, and that let the forestay go slack.

Another lesson learnt the hard way!!!