|

New maritime regulations mean that holding tanks must be fitted to all boats that use enclosed waterways.

For a while I explored the feasibility of a Porta Potty but

the inconvenience of emptying it tends to outweigh the ease of fitting. The manual Brydon Boy marine toilet commonly fitted

to RL28s has proven to be reliable and requiring little maintenance, with parts still readily available. But the RL28 was

designed long before holding tanks were fitted to boats of this size, so no provision was made for retro fitting.

I have seen various locations used including under the bunks, and toilets with integral holding tanks. The problem with the former

is that it requires changes to seacocks locations, and more holes in the hull, or long lengths of outlet pipes. The integral toilets

are quite large and the limited space in the RL28 head is not really suitable for these.

I wanted as few changes to the plumbing as possible with definately no extra holes in the hull. This meant the holding tank

had to be located near the bilge area where the seacocks are located. The only available space is the storage area under

the forepeak bunk. While this is smaller than optimal, the volume would be sufficient for a couple of weeks of use. Then the

decision of whether to try sealing it into a tank or simply putting a flexible holding tank in. Predictably I went for the

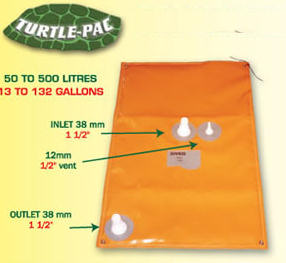

lazy option of the flexible tank. These are built at the Gold Coast and available at most chandleries in a range of sizes.

I selected the 100 litre tank although, because of the limited height, will probably only hold half this.

The storage area is too narrow for this size but there is no problem in bending the bag up at the sides to fit.

The biggest problem is the lack of height. The tank's inlet pipe is in the middle of the tank and attached vertically.

There is no way it will fit in the space available. So after contacting the manufacturer, decided to use the outlet pipe

(that enters horizontally at one end), for the inlet and outlet.

I cut the original inlet pipe down to where the BSP thread starts, and attached an end cap to seal it off permanently.

Similarly the breather pipe is quite long and I cut this back to the BSP thread and fitted an elbow.

The breather pipe leads into the head and runs up the wall, through the deck, and up into a stanchion, so it can be

sealed at the deck.

The manufacturer strongly recommended fitting a valve at the tank so that it can be isolated when work is needed on the toilet

or any of the pipes. Because of the limited space in the bilge area, the only place for the valve is in the storage area where

the holding tank is fitted. There is lots of room for the valve here because the holding tank is shorter than the storage area.

I fitted a PVC ball valve - it is the cheapest option.

I tried a range of fittings to join up the components. The best would be a Y valve but there is just no room to fit it in the bilge area.

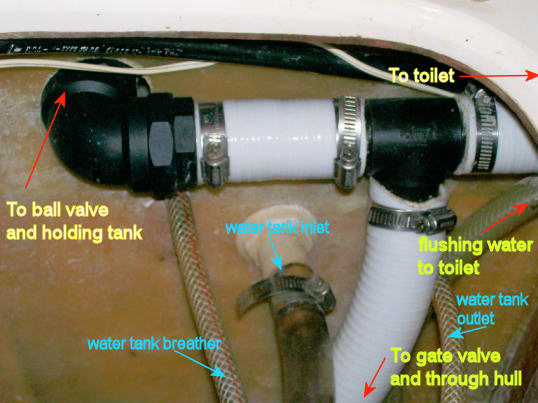

Finally the one difficult job: removing the existing pipe from the toilet to the seacock and replacing it with a T piece

leading to the toilet outlet, the holding tank, and the seacock via a gate valve.

These pipes have very thick walls and are relatively short and so bend very little. The secret is to fit as many as possible

to the T piece before locating it into its final position. Then the pipe can be soaked in boiling water to soften it.

There is VERY little room to maneuver the pipes in the bilge area but quite a bit in the head and tank areas,

so leave those till last.

The water tank outpet pipe may need to be bent to keep it out of the way of the toilet pipes. Be careful not to crimp it.

Unfortunately, one end of the T Piece to seacock pipe must be fitted insitu.

I got the pipe as hot as possible by simply pouring boiling water over it and found that hammering the T Piece down

into the pipe with a rubber mallet seemed to work - after a lot of hammering. Fortunately the T piece took the abuse.

Later, it was suggested that a heat gun can help soften the pipe when it can't be soaked in boiling water if in an inaccessible place. (Now they tell me!)

Advantages of this method:

The lowest cost option. The only expensive items are the holding tank $220, and the ball valve $25, 1.5 metres of 1 1/2 toilet pipe $35, and another $30 of assorted plumbing fittings

The least changes to the plumbing.

The least obtrusive option.

Disadvantages:

Limited tank holding capacity

There is no provision for pumping out into a disposal station so it requires that the boat be sailed into open

water regularly to empty the tank. If compulsory pump out is introduced, the system will need to be modified.

As it relies on gravity to empty, it may require some Porta Potty fluid be used to help break down the contents.

There is one type designed specifically for salt water.

Finally, the old Brydon Boy had a macerator as part of its pump but this may not meet the requirements of the new legislation.

One solution is, if the toilet is aging, replace it with an electric toilet which does have the required macerator. The

TMC chinese-made electric toilets are not a lot dearer than a complete kit of parts to repair the existing Brydon Boy.

. .

Turtle Pac are the manufacturers of the holding tanks.

|